July 2003, Issue No. 207

A monthly report on

environmental and pesticide related issues

A monthly report on environmental and pesticide related issues

Open Forum: In an attempt to promote free and open discussion of issues, Agrichemical and Environmental News encourages letters and articles with differing views. To discuss submission of an article, please contact Dr. Allan Felsot at (509) 372-7365 or afelsot@tricity.wsu.edu; Dr. Catherine Daniels at (253) 445-4611 or cdaniels@tricity.wsu.edu; Dr. Doug Walsh at (509) 786-2226 or dwalsh@tricity.wsu.edu; Dr. Vincent Hebert at (509) 372-7393 or vhebert@tricity.wsu.edu; or AENews editor Sally O'Neal Coates at (509) 372-7378 or scoates@tricity.wsu.edu. EDITORIAL POLICY, GUIDELINES FOR SUBMISSION.

Go to Agrichemical and Environmental News Index

Go to WSPRS (Washington State Pest Management Resource Service) Home Page

Do Buffers Make Good Neighbors?

Minimizing Pesticide Exposure at the Ag-Urban Interface

Dr. Allan Felsot, Environmental Toxicologist, WSU

From

Apples to Houses

From

Apples to Houses

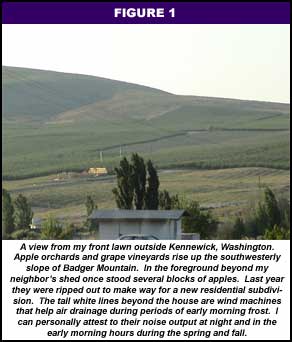

Ten years ago my front window yielded a panorama of nothing but orchard creeping up the backside of Badger Mountain. But as the price of apples went down, the trees were uprooted to make way for tracts of houses (Figures 1, 2). Such scenes are being repeated throughout agricultural regions everywhere as suburbia intertwines with agriculture. Whether it’s progress depends on your viewpoint, but conflicts may arise as former urbanites receive an intimate education about modern commercial agriculture.

Life on the Farm

Farm operations kick off early in the day. The noise, smell, smoke, and dust are visible reminders of a green factory hard at work. Of course, other urban enterprises have visible and audible side effects, so if wanting to strangle the rooster at 4 am were the worst of it, most folks probably wouldn’t have a problem co-existing with production agriculture.

But

there are other activities inherent to farming that concern non-farmers

and can lead to neighborly conflicts. Some people worry the minute they

see a spray rig, regardless of the intended spray location. People with

respiratory problems worry when they see field burning in progress. Add

to this cautionary or even alarmist headlines about pesticide drift, and

reasonable concerns can become paranoia or panic.

But

there are other activities inherent to farming that concern non-farmers

and can lead to neighborly conflicts. Some people worry the minute they

see a spray rig, regardless of the intended spray location. People with

respiratory problems worry when they see field burning in progress. Add

to this cautionary or even alarmist headlines about pesticide drift, and

reasonable concerns can become paranoia or panic.

Pesticide use is intrinsic to conventional and organic agriculture alike. The physics of drift make some pesticide movement off-target likely. Practices to minimize drift are required. Nevertheless, pesticide drift can be considered a form of trespass. So how can growers continue to pursue their livelihood while sharing borders with residential neighbors?

Neighborly Relations

One way growers can avoid conflict is by judiciously employing vegetative buffer zones. Part of the reason buffers work is illustrated by the old adage “out of sight, out of mind.” Screening operations behind solid stands of trees and bushes not only reduces the visual impact of farming operations, it cuts down noise and dust. Further, no-spray buffer zones can reduce potential pesticide hazards to insignificance by minimizing exposure.

The question is, how large does a buffer zone have to be to be effective? The question is more than theoretical as county planning agencies permit the development of residential areas among working orchards and other cropping systems.

My Involvement with Buffers (or “Does Size Matter?”)

My interest in appropriate sizes of buffer zones began in the 1990s with an examination of spray drift from Christmas tree plantations, with an emphasis on whether prescribed buffer zones were adequate for protecting water quality (Felsot et al. 2003). Then, in 1997, the Benton County Planning Commission asked me to determine the size of buffer zone needed to protect a planned residential area against potential spray drift from an adjacent orchard. In this case, the land developer was going to be required to leave an undeveloped area between the house lots and the orchard. Although growers can and often do leave unsprayed rows in their fields or orchards as a voluntary measure, county “Right-to-Farm” laws dictate that new land uses in established agricultural zones must yield to the interests of the farms.

To determine a reasonable size for a buffer between the orchard and residences on the planned adjacent lots, I needed two pieces of information:

- the deposition of spray downwind of the last row treated, and

- the toxicological properties of the pesticides being used along with tolerable levels of exposure.

First,

to estimate (or predict) the deposition of spray, I used a mathematical

equation developed from drift data measured in an experimental orchard

at Ohio State University (Fox et al. 1993). At the time of the Planning

Commission’s request, this was one of the best models available

to me. Later, the drift simulation model AgDrift was publicly released,

making estimation of drift from ground and aerial spraying easier (Figure

3).

First,

to estimate (or predict) the deposition of spray, I used a mathematical

equation developed from drift data measured in an experimental orchard

at Ohio State University (Fox et al. 1993). At the time of the Planning

Commission’s request, this was one of the best models available

to me. Later, the drift simulation model AgDrift was publicly released,

making estimation of drift from ground and aerial spraying easier (Figure

3).

Next, I needed information about the toxicological properties of the pesticides used in the orchard and levels of exposure accepted by the U.S. EPA as constituting a reasonable certainty of no harm. The tolerable exposure level is by regulatory tradition called the reference dose. It represents the NOAEL (No Observable Adverse Effect Level for the most sensitive physiological hazard) divided by a safety factor of at least 100. All of this information is available from EPA’s Reregistration Eligibility Decision Documents (http://www.epa.gov/pesticides/reregistration/status.htm) or by searching for specific pesticide tolerance petitions that are published in the Federal Register.

To make a long story short, I estimated that at least 150 ft (~50 m) should be left undeveloped between a fixed residential structure and the last row of the farm (see sections below for an explanation of methodology). Since that time, however, I’ve been wondering just how conservative drift modeling is.

Toxicological Relevance and AgDrift

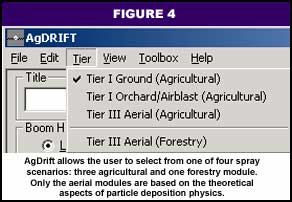

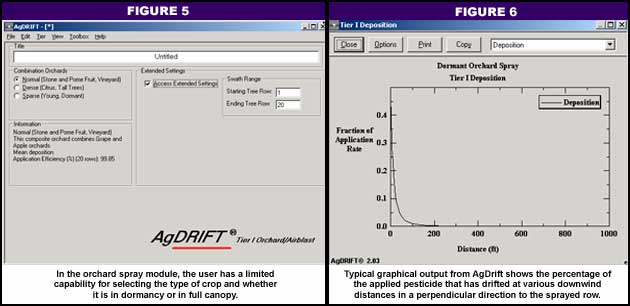

The

AgDrift model has three agricultural components or modules: ground spraying

with a boom mounted four feet or less from the ground, orchard spraying

with an airblast sprayer, and aerial spraying with either a fixed wing

aircraft or helicopter (Figure 4). The aerial spraying module is based

largely on the theory of particle movement and deposition (Teske et al.

2002). It relies on a library of nozzles for which the spray aerosol size

distribution is known. The aerial module can be manipulated to account

for various meteorological parameters (e.g., wind speed and direction,

temperature, humidity, surface roughness). In contrast, the ground and

orchard spraying modules are empirical in nature, based on numerous experimental

studies. Their limitation is that they do not rely on the physics of particle

movement but rather on a mathematical description of the studies that

were used to make the model. Thus, meteorological characteristics cannot

be altered in these modules. The orchard model, however, can simulate

a dormant spray and a full-canopy spray (Figure 5, 6).

The

AgDrift model has three agricultural components or modules: ground spraying

with a boom mounted four feet or less from the ground, orchard spraying

with an airblast sprayer, and aerial spraying with either a fixed wing

aircraft or helicopter (Figure 4). The aerial spraying module is based

largely on the theory of particle movement and deposition (Teske et al.

2002). It relies on a library of nozzles for which the spray aerosol size

distribution is known. The aerial module can be manipulated to account

for various meteorological parameters (e.g., wind speed and direction,

temperature, humidity, surface roughness). In contrast, the ground and

orchard spraying modules are empirical in nature, based on numerous experimental

studies. Their limitation is that they do not rely on the physics of particle

movement but rather on a mathematical description of the studies that

were used to make the model. Thus, meteorological characteristics cannot

be altered in these modules. The orchard model, however, can simulate

a dormant spray and a full-canopy spray (Figure 5, 6).

Bystander contact with organophosphorus insecticides is the greatest inadvertent exposure concern in fruit production, so we set about studying that type of exposure. During crop year 2002, we received permission to set up an experiment in a block of Gala apples at a commercial orchard located west of Quincy, Washington.

Airblast sprayers are most commonly used to apply insecticides in orchards and vineyards. Application usually takes place once or twice a growing season. In our test orchard near Quincy, we ran an airblast sprayer between the first and second rows, then the second and third rows (Figure 7). We reasoned that less drift would be measurable outside of the orchard if we left the outside rows unsprayed. In each case, we sprayed only a single row and measured the drifting spray depositing both outside and within the orchard.

|

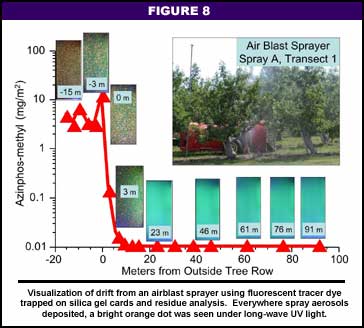

To trap the depositing spray aerosols, we laid on the ground silica gel cards (aka “drift” cards, 20 cm x 10 cm) along a transect perpendicular to the row to a distance of 300 feet (91 meters) outside of the orchard and 50 feet (15 meters) within the orchard. Two transects were measured for each spray run. We loaded Guthion (azinphos-methyl insecticide) and a fluorescent Day-Glo dye into the tank. After a single row was sprayed, we picked up the cards, photographed them under ultraviolet light, and then we extracted them to measure Guthion residues. For each spray, the wind was light and variable, but tended to blow across the transect rather than parallel with it. Examination of the cards under UV light revealed bright orange spots wherever spray aerosols deposited on the surface (Figure 8). We could see that treating a single row caused movement of the spray several rows within the orchard. However, we could detect the fluorescent dye only 10 feet outside of the orchard. Our analytical method for actual Guthion residues was more sensitive then our ability to visualize the fluorescent dye. Nevertheless, we only detected Guthion residues to a maximum distance of 30 feet (9.1 meters) from the outside tree row. I was curious to see how well AgDrift would simulate an actual application in central Washington. I ran the AgDrift model to simulate a one-row spray—either a spray between rows one and two or between rows two and three (Figure 7). In each case, I noted that AgDrift over-predicted measured drift in the region near the orchard (Figure 9). Although the creators of the AgDrift model claim that wind is not a very important factor in drift from orchards (presumably because of the calming effect of the canopy) (Teske et al. 2001), the light winds blowing across the transect may have dampened drift away from the orchard. Nevertheless, I have concluded that simulations of orchard spraying with AgDrift is conservative enough to allow its use for designing no-spray buffer zones to protect bystanders. |

Changing Residues into Doses

Once residues have been determined, the next step in designing a toxicologically protective buffer zone is to translate depositing residues into a whole body dose. Drift is often expressed as the mass of residues depositing on a given surface. For example, one common expression of drift is mg/m2, as shown in Figure 8. If we knew the surface of a person’s body, we could very conservatively assume that either all or some fraction of their body surface is exposed. Dividing by the body weight would yield a dose in units of mg/kg. These units are conveniently the same as the units used in the reference dose (RfD).

The most conservative bystander to protect would be a small child because children have the highest surface area per unit of body weight. The EPA has estimated for a 10 kg child that the 95th percentile of surface area is 0.682 m2 (U.S. EPA 1997). Using this value and an assumption of 100% dermal absorption of any depositing insecticide residues, the whole body dose can be calculated. For example, if a child were positioned directly under a spray applied at the rate of 1 lb of active ingredient per acre (AI/acre), which is equivalent to 1.124 kg AI/ha, then the body exposure would be 7.6 mg/kg (i.e., 1.124 kg/ha * 1 ha/10000 m2 * 1000000 mg/kg * 0.682 m2 / 10 kg). If dermal absorption or penetration of the pesticide were 100% efficient, then 7.6 mg/kg would represent a whole body dose rather than just dermal exposure. Actual exposure would be adjusted by any dermal absorption efficiency less than 100% to yield the whole body dose. Using similar reasoning, any drifting residue beyond the orchard could be transformed to a whole body exposure and then adjusted by the dermal penetration efficiency to obtain the whole body dose.

Toxicologically Relevant Buffer Zones for Pome Fruit Insecticides

Of all the insecticides currently registered for orchard use after bloom, Guthion (azinphos-methyl) is used the most and is the most hazardous with respect to the acute oral LD50 (4.4 mg/kg) and dermal LD50 (155 mg/kg) (Table 1). Thus, any buffer zone derived for Guthion should also provide protection for use of all other pesticides. There is one exception: Lorsban (chlorpyrifos). Lorsban is registered for use only during apple dormancy. Although it is significantly less hazardous than Guthion from an acute toxicity perspective, EPA has assigned an extra 10-fold safety factor to its NOAEL, making it seem relatively more hazardous than Guthion with respect to its RfD (Table 1). All other compounds used currently in orchards have low oral and dermal toxicity and are inefficiently absorbed through the skin (Table 1).

TABLE 1 |

|||||

|

Toxicological

Profiles for Conventional and Reduced-Risk |

|||||

| Estimated no-spray buffer zones assume the dermal absorption efficiencies as shown in the adjacent column. Note that carbaryl is mostly used as a fruit thinner, not an insecticide. Toxicological data, dermal absorption efficiency, and RfDs come from EPAs Registration Eligibility Decision Documents and Petition Tolerances published in the Federal Register. Estimated buffer zones are calculated based on the information presented in this article. | |||||

| Pesticide |

LD50

Oral

(mg/kg) |

LD50

Dermal

(mg/kg) |

Acute

RfD or PAD

(mg/kg/day) |

%

Dermal Absorption

|

Estimated

Buffer Zone (ft)

|

| azinphos-methyl | 4.4 |

155 |

0.003 |

42 |

70 |

| chlorpyrifos | 223 |

222 |

0.0005 |

3 |

275 |

| phosmet | 113 |

5000 |

0.045 |

10 |

0 |

| carbaryl thinner | 307 |

2000 |

0.01 |

12.7 |

5 |

| acetamiprid | 1064 |

2000 |

0.1 |

30 |

0 |

| methoxyfenozide | 5000 |

2000 |

0.1

(1) |

3 |

0 |

| (1) EPA has not defined an acute RfD for methoxyfenozide owing to lack of short term toxicity. However, the chronic RfD, which is based on two-year feeding studies is 0.1 mg/kg/day. | |||||

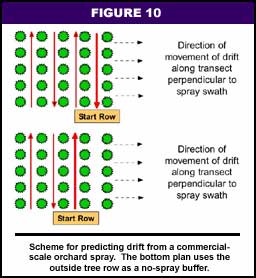

To

determine a toxicologically relevant no-spray buffer zone for Guthion,

I estimated drift from a 20-row spray starting with rows one and two (Figure

10). I repeated the simulation starting from rows two and three, essentially

using the outside row as an extra buffer (Figure 10). The drift residues

depositing on the ground were expressed as a whole body dose assuming

100% dermal absorption. Whole body exposure was also adjusted by the dermal

absorption efficiency of 42% that was discussed by the EPA in the Registration

Eligibility Decision Document for azinphos-methyl (http://www.epa.gov/pesticides/reregistration/status.htm).

To

determine a toxicologically relevant no-spray buffer zone for Guthion,

I estimated drift from a 20-row spray starting with rows one and two (Figure

10). I repeated the simulation starting from rows two and three, essentially

using the outside row as an extra buffer (Figure 10). The drift residues

depositing on the ground were expressed as a whole body dose assuming

100% dermal absorption. Whole body exposure was also adjusted by the dermal

absorption efficiency of 42% that was discussed by the EPA in the Registration

Eligibility Decision Document for azinphos-methyl (http://www.epa.gov/pesticides/reregistration/status.htm).

The estimated no-spray buffer zone meeting EPA’s standard of reasonable certainty of no harm was 160 feet from tree row one if the sprayer line of travel was between the first two rows (Figure 11). This buffer zone assumes that Guthion was 100% absorbed. When a more realistic assumption of 42% dermal absorption efficiency is applied, the no-spray buffer zone drops to 70 feet (Figure 11).

The effect of not spraying the outside two rows can be seen in Figure 12. With an assumption of 100% dermal absorption efficiency, the no-spray buffer zone drops to 140 feet. With the more realistic scenario of partial dermal absorption, the zone drops to 55 feet.

The buffer zones I estimated for other commonly used and new insecticides are listed in Table 1. Note that chlorpyrifos has an even larger estimated buffer zone than Guthion despite being of lower acute toxicity and higher RfD. As mentioned earlier, chlorpyrifos has been assigned an extra 10-fold safety factor owing to EPA’s concerns about child sensitivity. The resulting figure of 0.0005 mg/kg is considered to be a child protective Population Adjusted Dose (PAD). In addition to having a more protective standard, chlorpyrifos will tend to drift more because it is applied during dormancy, when a lighter canopy is present to filter out drifting residues. Finally, Lorsban residues downwind of the spray line will be higher than Guthion because its application rate is double the typical Guthion rate (2 lbs AI/acre vs. 1 lb AI/acre).

An important point to consider is the extreme conservatism of these buffer zone calculations. I assumed that every nook and cranny of body surface would be exposed to drifting spray. Of course we may want to account for the lifestyles of the neighborhood nudist colony, but for the overwhelming majority of us, such a scenario is unlikely.

Who Is Responsible for No-Spray Buffers?

My county’s planning commission has spoken loud and clear regarding responsibility for buffer zones. If a planned residential community is going to sit adjacent to a functioning farm, the developer is going to have to leave sufficient undeveloped land along the border to reduce the chance of exposure to not only spray drift but to the other operations of the farm.

Even

if a grower is not affected by creeping suburbia, he or she may want to

leave unsprayed rows around the borders of cropping areas if these areas

are very close to sensitive habitats like streams. If an orchard is adjacent

to undeveloped lands, a no-spray zone may benefit the potential biocontrol

functions of the beneficial insects harbored in the vegetation. Another

reason to consider leaving unsprayed border rows is the proximity of other

crops for which the pesticide is not registered.

Even

if a grower is not affected by creeping suburbia, he or she may want to

leave unsprayed rows around the borders of cropping areas if these areas

are very close to sensitive habitats like streams. If an orchard is adjacent

to undeveloped lands, a no-spray zone may benefit the potential biocontrol

functions of the beneficial insects harbored in the vegetation. Another

reason to consider leaving unsprayed border rows is the proximity of other

crops for which the pesticide is not registered.

Buffers: One Strategy Among Many

When growers are considering buffering their spray operation, they must keep in mind that not protecting all of their trees could make them vulnerable to pest outbreaks. Thus, judicious application of IPM principles for pest population monitoring is an essential companion to any spray management program.

Since human health is the bottom-line issue for these discussions, growers seeking management strategies may want to try the new reduced-risk insecticides that have been registered within the last year or two. For pome fruits, Intrepid (methoxyfenozide) and Assail (acetamiprid) (Table 1) can be effective substitutes for Guthion, especially if codling moth populations are low. Just remember that the perception of chemical trespass is not based on toxicity. Any legal judgment would likely reflect the danger level of the material, but any detection of residues is technically drift.

Land

developers can be good neighbors by planning buffer zones that are irrigated

and vegetated. For example, planting a stand of tall trees like poplars

can be an effective barrier for physically trapping drifting spray while

also cutting down on noise, dust, and odors (Figure 13, 14). Because poplars

may have a limited life span, slower growing coniferous trees can be planted

adjacent to the rapidly growing poplars to serve as a more permanent vegetative

barrier. Whenever planning a tree-lined buffer, developers should consider

air drainage characteristics of the upwind orchard and leave gaps in the

trees (Figure 13).

Land

developers can be good neighbors by planning buffer zones that are irrigated

and vegetated. For example, planting a stand of tall trees like poplars

can be an effective barrier for physically trapping drifting spray while

also cutting down on noise, dust, and odors (Figure 13, 14). Because poplars

may have a limited life span, slower growing coniferous trees can be planted

adjacent to the rapidly growing poplars to serve as a more permanent vegetative

barrier. Whenever planning a tree-lined buffer, developers should consider

air drainage characteristics of the upwind orchard and leave gaps in the

trees (Figure 13).

In summary, buffer zones are another technique for managing spray drift. When protecting human bystanders, drift modeling in conjunction with a knowledge of EPA’s standards for reasonable certainty of no harm can be used to set toxicologically relevant no-spray zones. The results from this planning exercise will be very conservatively protective of humans and may help keep peace in the neighborhood.

Allan Felsot is an Environmental Toxicologist with the Food and Environmental Quality Laboratory on the Tri-Cities campus of Washington State University. He is a frequent contributor to AENews and can be reached at afelsot@tricity.wsu.edu or (509) 372-7365.

REFERENCES

Felsot, A. S., S. Foss, J. Yu. 2003. Deposition of pesticides in riparian buffer zones following aerial applications to Christmas tree plantations. In Pesticide Science: Environmental Fate & Effects of Pesticides, 3rd Edition. J. Coats and H. Yamamoto (ed.), Oxford University Press. 288 pp. ISBN #0-8412-3722-0.

Fox, R. D., et al. 1993. Downwind residues from spraying a semi-dwarf apple orchard. Transactions of The ASAE 36(2):333-340.

Teske, M. E., S. L. Bird, D. M. Esterly, T. B. Curbishley, S. L. Ray, and S. G. Perry. 2002. AgDRIFT: a model for estimating near-field spray drift from aerial applications. Environ. Toxicol. Chem. 21(3):659-671.

Teske, M. E., S. L. Bird, D. M. Esterly, S. L. Ray, and S. G. Perry. 2001. A User's Guide for AgDRIFT 2.03: A Tiered Approach for the Assessment of Spray Drift of Pesticides. C. D. I. Report No. 01-01, Steward Agricultural Research Services, Inc., Macon, Missouri.

U.S. EPA. 1997. Exposure Factors handbook. Volume 1-General Factors. EPA/600/P-95/002Fa, Office of Research and Development, National Center for Environmental Assessment, U.S. EPA, Washington, DC.

Go to this issue's Table of Contents

Go to Agrichemical and Environmental News Index

Go to WSPRS (Washington State Pest Management Resource Service) Home Page

A QBL Edict to Registrants

Mean What You Say and Say What You Mean

Jane M. Thomas, Pesticide Notification Network Coordinator, WSU

(ED. NOTE: In an ongoing effort to elicit a job offer from the U.S. Environmental Protection Agency (EPA), Her Royal Highness The Queen Bee of Labels (HRH QBL, a.k.a. WSU's Jane M. Thomas) takes time out of her busy Royal Schedule periodically to point out oddities and aggravations on pesticide labels. It is the QBL's Opinion Most High that if she were in charge of all things label, a few RULES, combined with swift and thorough consequences for transgressors, would whip the whole pesticide label business into shape in a matter of weeks. Until such time as EPA sees the light and appoints HRH QBL to her rightful position, The Queen shall content herself with commentaries such as the following article.)

Hello,

hello! 'Tis I again, the Queen Bee of Labels (QBL to you). That's right,

it is time for you to once more break out your genuflections. Oooh, I

hear those knees cracking from here. My fault, really, since it has been

so long. Consider this a Royal Apology. Not to make excuses, but things

have been a bit busy around the palace. President Bush has been putting

additional pressure on EPA and I am sure that that ever-tardy agency will

soon formally ask me to assume my Rightful Royal place as the (official)

QBL (See "If

I Were the Queen of Labels," AENews Issue No. 169, May

2000).

Hello,

hello! 'Tis I again, the Queen Bee of Labels (QBL to you). That's right,

it is time for you to once more break out your genuflections. Oooh, I

hear those knees cracking from here. My fault, really, since it has been

so long. Consider this a Royal Apology. Not to make excuses, but things

have been a bit busy around the palace. President Bush has been putting

additional pressure on EPA and I am sure that that ever-tardy agency will

soon formally ask me to assume my Rightful Royal place as the (official)

QBL (See "If

I Were the Queen of Labels," AENews Issue No. 169, May

2000).

In light of my six-month hiatus from these pages, I am now considering changing my Royal Motto from "No More Lousy Labels" ("E pluribus electrolux fusarium helvetica," explained in "HRH QBL Asks: Wherefore Art Thou, Revision Information?" AENews Issue 173, September 2000) to “Tardy But Untarnished: The QBL Rules.” In the final analysis, the best way to atone for my absence is to return with full vigor to my True Purpose of dispensing wise and queenly council. Let it be known that I am once again on the throne. With keyboard at hand, I am ready to proceed.

Reflections from the Princess Years

Now in my silver years (yes, those are silver hairs!) and past the point of worrying about Palace Politics, I have time to reflect. I find there are many things I learned as a young princess that have served me well over time. The one that has most recently come to mind is something that we used to say when playing around the palace. Anytime one of the Royal Children made a verbal slip, the rest of us would reply with, "Say what you mean and mean what you say." (Yes, even we royals have been known to taunt one another on occasion as children.) I think that this edict is sufficiently pertinent that I am tempted to make it one of my twelve Royal Rules. As I have proclaimed for years, if there were a few RULES in place regarding pesticide labels, we would not see the mess that we do with current labeling. Hence the Royal Rules. So much thought was given to these rules that one does not contemplate tampering with them lightly. In the final analysis, a thirteen-step recovery program for pesticide labels (rather than the standard twelve steps) offended my sense of symmetry.

Dow's Muddy "Water"

Despite my careful explanations and obvious Royal Qualifications, new readers may still be wondering, "What is with this QBL person?" To you I say, let us simply look at a few labels together; enlightenment will follow. We begin with an example that was brought to the Royal Attention by WSDA's ever-vigilant Byron Fitch. Please take a moment to look over Dow's Telone C-17 label, EPA Registration Number 62719-12. (Or, feel free to review ANY of Dow's Telone labels, C-17, C-35, EC or II, as all contain the error on which we will focus. For your convenience, however, I provide an excerpt from the Telone C-17 label below.) In the Storage, Shipment, and Disposal section of the label, Dow cautions, "Because Telone...is corrosive under certain conditions, flush all application equipment with fuel oil, kerosene, or a similar type of petroleum solvent immediately after use...Do not use water." Conversely (or perhaps perversely) under the Environmental Hazards information, Dow’s label states the following: "Do not contaminate water by disposal of equipment washwaters (emphasis added)."

Why, if one is to refrain from using water to rinse equipment, does Dow use the word washwaters? What would be so hard about changing this word to R-I-N-S-A-T-E? This is so simple and is such a good idea that another Telone registrant, Trical (Telone C-15, EPA Registration Number 11220-20) has done exactly that. Now if Trical, who I assume is a smaller entity than Dow, can get it right, what is Dow's excuse? Dear Dow, I am not being cruelly critical; I am attempting to gently nudge you in the direction of saying what you mean and meaning what you say. Please heed my nudges and move along the path of rightness and clarity. Take yourself to a better place! Do better, be better! Think clearly, speak clearly, and write clearly! Did you think that I wrote up those Royal Rules just to hear my fingers clicking on the Queenly Keypad? For shame.

Phaser Labels Simply Stunning

Let us give Dow a moment to quietly reflect on its transgressions before we move along to the next example. I'm sure many of my Fearless Followers will remember Laddock S-12, the nefarious example of a Litigious Layout in "The QBL Gets Graphic" (AENews Issue No. 176, December 2000). This was a spectacular example of a poor label layout sure to cause confusion among the label-reading public. Apparently you registrants, or at least those at Bayer, weren't paying attention. WSU's own Catherine Daniels, Director of the illustrious Washington State Pest Management Resource Service, brought this example to the royal attention. Please take a look at Bayer's Phaser 50 WSB Insecticide label (EPA registration number 364-656).

On the front cover of this label, using all capital letters, Bayer makes it more than clear that this product is not for use in California. That seems straightforward enough; however, by the time one flips to page 3 one begins to think that perhaps this label has a split personality. Here it appears that Bayer is saying both "don't use this product" in the golden state and just beneath this directive, telling applicators to "use this product" in California. Finally, to make it more confusing still, the final line reads, "For Use in California."

I wondered if the entire Phaser product line had this sort of dementia. Perhaps it was catching. Maybe I should wash the Royal Hands after handling these labels lest the problem rub off and the QBL should, heaven forbid, begin babbling nonsense. (No comments, please, from Court Critics.) But upon reviewing the Phaser 3 EC Insecticide label (below), things became clear. It seems that Bayer was trying to tell us that if you want to use Phaser 50 WSB in California then in place of reaching for a product called Phaser 50 WSB Insecticide you should be palming a product called Phaser 50 WSB Insecticide For Use in California. Again, this only became clear after looking at Bayer’s Phaser 3 EC label, as follows.

There are four things that would have made Bayer’s message on its Phaser 50 WSB label clearer:

- drop the U in the first Use to lower case,

- place a comma after this "use,"

- make sure that the entire product name fits on one line, and

- somehow (bold or italics) emphasize or set apart the portion of the second line that is the product name.

Interestingly enough, both the Phaser 3 EC and Phaser 50 WSB labels were received from Bayer with Washington’s 2003/2004 registration materials. Both are apparently revised labels and therefore represent the most recent copy of each that Bayer has produced. It is odd that Bayer has eliminated confusion on the Phaser 3 EC label but has done such a poor job on the Phaser 50 WSB label. Really, Bayer, these are little things. They aren’t too much to ask. If you want to land on the Royal Rightside, then say what you mean. In this case, judging by the information that appears on the label, I don’t think that Bayer meant what they said.

FMC Using Unique Units

I have one last label to bring up: FMC’s Thiodan WSB Insecticide (EPA Registration Number 279-3129). This label was brought before the Royal Eye and receives the Royal Ire thanks to WSU’s Geri Leonard. Diligent Program Assistant that she is, Geri reviews WSU publications to ensure that any pesticide recommendations made are in keeping with label directions. This is a daunting task (just ask Geri!) but one she dispatches with such grace and style that one wonders of her background. Could she be a Royal Changeling?

When I was faced with questions about Thiodan WSB I telephoned FMC's registration office and asked to speak to the Thiodan product manager. I ended up speaking to a product manager at Makhteshim-Agan. I interpret this to mean that FMC has sold this product. However, because WSU’s ever-accurate PICOL label database says that the registrant is FMC, I am assigning the blame for this label confusion to FMC. Once PICOL says otherwise, Makhteshim-Agan watch out! (Those not familiar with the PICOL Label Database should really avail themselves of this marvelous Regal Resource, maintained by WSU's astonishingly accurate Database Coordinator Charlee Parker.)

But I digress. Back to Thiodan WSB. Two problems appear on page 3 of the label. The first comes under the directions for use on barley, oats, rye, and wheat, small grains one and all. For aphid control, the label directs growers to use 2 to 3 bags per acre; however, under the crop-specific restrictions, the label admonishes users not to exceed 2 bags per acre per year (below left). (I will not dwell upon my further observation that the notes under method of application for aphid control have been cut off and make no sense.) My helpful contact at Makhteshim-Agan did some research and found that the label should have stated that the use rate was 2 to 3 bags per 2 acres. Even though an explanation was provided, the QBL does not approve. Who has ever heard of giving directions for use in terms of anything "per 2 acres?" Even if the rate had worked out to a half a bag per acre, Royal Thought holds that no right-minded registrant would word a label saying the rate was 1 bag per 2 acres. It just isn’t seemly. I will now go on record as stating that were a case of a 3-bag application to oats brought to my Royal Court I would not find fault with the applicator. I would insist that the registrant, whomever that should be, would be responsible for sowing more oats for the faultless farmer. This label is definitely a nominee for the QBL’s 2003 Down the Garden Path Non-Anom award (see AENews Issue No. 184, August 2001).

All this "per 2 acres" business made me look a bit more closely at this label than I normally might have. Please take a look at the Mustard Greens directions (below right). Here FMC (or whomever) gives some of the rates in "bags per 2 acres." Fine. Now look at the directions for use for whitefly control. Here the rate is again in bags per acre. What sort of nonsense is this? One does not give one use rate for one pest and a use rate in separate units for a different pest on the same label let alone the same crop. FMC, please pick a unit and stick to it!

Now let us drop our eyes to

the Thiodan WSB directions for use on “Beans, Succulent and Dry

(except Lima Beans)" shown below. In the crop-specific restrictions

the label reads, “Do not use on Lima Beans that are to be removed

from the field for processing.” In keeping with today’s theme

of "mean what you say and say what you mean," I ask, what does

THIS mean? If I grow lima beans for fresh market sales, can I use this

product? If I set up a small in-field processing plant, can I use this

product? I asked the aforementioned Makhteshim-Agan representative and

she was clear that the product could not be used on lima beans but had

no explanation for this queerly worded restriction. Again, in my Court,

if a fresh market lima bean grower had been found using this product and

it led to a crop which he or she could not market, the Royal Wrath would

reverberate off the registrant not the farmer. Visions of thumbscrews

dance around in the Queenly Bean Brain.

I really did not intend to go on and on (and on) about the Thiodan label but…I have one last observation. This concerns Succulent Peas. The QBL really does not care for lima beans, fresh or processed, but peas are a different matter altogether and one should not tamper with pea use directions. Here (see above) FMC is back to giving the rate in bags per one acre but below, in the crop-specific restrictions, note that FMC states not to exceed 2-2/3 quarts per acre per year. I have nothing further to say about this label except I am very, very disappointed in FMC (to say the least).

QBL's Parting Shot

Please, registrants, give the farmers a break. Look your labels over. Go ahead: review them for errors, omissions, and clarity. I'm not talking about the copies that you send to EPA; I don’t particularly CARE what you send EPA. Review the marketing label, the one the end-user is forced to make sense of. If you can’t do it yourself (and, for many, it is hard to adequately review one's own creation), then hire someone else to review your labels for you. That's what editors are for.

Registrants, clear up those confusions! Be succinct! Be precise! In short, mean what you say and say what you mean! For heaven's sake, just follow the Royal Rules. And then go forth with the QBL’s blessing and enjoy the rest of the summer.

Jane M. Thomas, a.k.a. Her Royal Highness the Queen Bee of Labels, spends her days (when not poolside) at WSU's Washington State Pest Management Resource Service (http://wsprs.wsu.edu), where she reigns over the Pesticide Notification Network (http://www.pnn.wsu.edu) and functions as the Pacific Northwest Comment Coordinator for the Western Region Pest Management Center while awaiting her Rightful Royal Coronation with the EPA. She can be reached at jmthomas@tricity.wsu.edu or (509) 372-7493.

Go to this issue's Table of Contents

Go to Agrichemical and Environmental News Index

Go to WSPRS (Washington State Pest Management Resource Service) Home Page

Cutworms Can Climb No More!

Barrier Technique Shows Promise, Conserves Beneficials in Vineyards

Dr. Doug Walsh, Extension Entomologist, Dr. Holly Ferguson, IPM Coordinator, and Ron Wight, Field Research Director

Cutworm is considered a key pest of grapes in southeastern Washington. These insects damage grapevines by feeding on the buds that are about to break and on the newly opened shoots. Buds injured by cutworm feeding may fail to develop, causing yield reduction. Some 30,000 acres of grape vineyard are estimated to be impacted in the region; essentially, no vineyard is exempt. Approximately 12,000 of these acres receive treatment against cutworm each year.

The typical control pattern for cutworm in southeastern Washington grape vineyards involves spraying a broad-spectrum organophosphate (OP) insecticide. A newer option is spraying a broad-spectrum pyrethroid. Unfortunately, these broad-spectrum pesticides can lead to outbreaks of secondary pests, particularly mites and mealybugs.

A better way to control cutworm would be useful to grape growers for a number of reasons. First, the insect is a widespread problem with a low economic threshold. One worm per four or five vines can be sufficient to cause concern and warrant treatment. Second, the most popular current treatment is chlorpyrifos (Lorsban). As an OP, chlorpyrifos is under fire from the U.S. Environmental Protection Agency as part of the reregistration process initiated by the 1996 Food Quality Protection Act. Third, both Lorsban and the various pyrethroids popularly used to control cutworm are broad-spectrum insecticides, making them less compatible with emerging integrated pest management (IPM) practices (note the comment on secondary pest outbreaks above). Fourth, current treatments for cutworm are almost exclusively in the form of foliar sprays. This delivery method can be costly (requiring a relatively large amount of pesticide for coverage) and can result in off-target deposition of the chemical. Motivated by this combination of factors, our research team at the Irrigated Agriculture Research and Extension Center (IAREC) in Prosser sought a lower-cost, more efficacious, and more IPM-compatible method for controlling cutworm in grape vineyards.

This article describes the results of our research toward this objective in 2002 and early 2003. In summary, we noted promising results in repelling cutworms by applying fenpropathrin (Danitol) at the base of grapevines in 2002. Application in this targeted fashion, where the soil, vine, and trellis meet, is known as "barrier treatment." Because of our success in 2002, we repeated this barrier treatment technique with Danitol as well as several other insecticides in 2003. The barrier treatments not only proved effective in reducing cutworm feeding damage in the experimental vineyard plots when compared to foliar treatments, this application method offers the additional advantages of lower cost and supporting the IPM principle of conserving beneficial insects.

Meet the CutwormsCutworms are inconspicuously marked, dull-colored caterpillars ranging from 0.6 to 2.0 inches (1.5 to 5 cm) in length. Several species of cutworms are pests of grapes grown on the Columbia Plateau and Yakima Valley. These include the spotted cutworm, Amathes c-nigrum (L.), and the red-backed cutworm, Euxoa ochrogaster (Guenee). |

|

|

|

| Fifth-instar spotted cutworms are about 1.3 inch (3.5 cm) long and are a dull gray brown. Distinctive dark or black triangular markings line each side of the back. Euxoa spp. cutworms are brownish or grayish with a yellow-brown head. They can reach 1.5 inches (3.8 cm) long during their fifth instar of development. The back is usually reddish or reddish-brown bordered with dark bands. The spotted cutworm overwinters as third-instar larva whereas Euxoa likely overwinters in the soil as an egg. Both species pupate after feeding ceases in spring. The subsequent second (and occasional third) generation are associated with other weed or crop hosts and are typically not damaging to grapes. |

Comparing Chemical Management Strategies

We began our experimentation in 2002 by comparing the efficacy of chlorpyrifos (Lorsban, a popular cutworm foliar spray) to other treatments, including barrier and foliar treatment with fenpropathrin (Danitol, a pyrethroid), foliar treatment with spinosad (Success, a fermentation product), foliar treatment with methoxyfenozide (Intrepid, an insect growth regulating insecticide), foliar treatment with indoxacarb (Avaunt, an oxadiazine insecticide), and bait treatment with carbaryl (Sevin, a carbamate). The barrier treatments were applied prior to bud swell and the foliar treatments were applied during the bud swell period. Barrier treatment with Danitol was the most effective at preventing subsequent feeding damage by cutworms. (ED. NOTE: Spinosad and methoxyfenozide were both recently registered for use on grapes. Indoxacarb is not registered on grapes in Washington.)

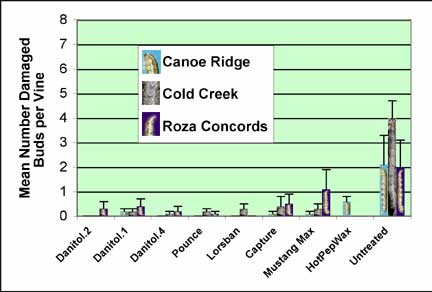

Our 2002 trials were conducted on small, fifteen-vine plots at three locations: Canoe Ridge near Paterson, Cold Creek near Desert Aire (both vinifera, wine grapes), and a Concord grape vineyard within the Roza irrigation system near Prosser. Figure 1 illustrates the results recorded at the Canoe Ridge site, which are representative of all three sites. (Data for the 2002 trials is available from the authors upon request.)

FIGURE 1 |

|||

| Cutworm

Trials at Canoe Ridge 2002 |

|||

|

|

Going into 2003, we decided to expand the studies for both barrier and foliar treatments. We conducted barrier and foliar treatment studies at all three sites: Canoe Ridge, Cold Creek, and Roza.

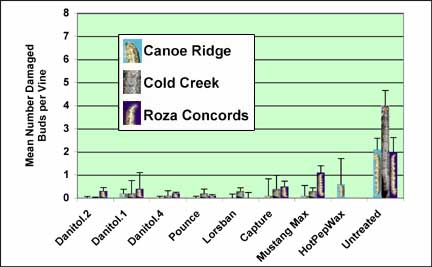

Given the exceptionally promising results of Danitol as a barrier treatment in 2002, we experimented with three concentrations of this product in our 2003 trials. We also tested barrier-treatment applications of the candidate pyrethroid insecticides zeta-cypermethrin (Mustang Max), bifenthrin (Capture), and permethrin (Pounce). ED NOTE: Neither zeta-cypermethrin, bifenthrin, nor permethrin is registered on grapes in Washington. As with Danitol, these were applied to the soil/vine/trellis interface. We also applied chlorpyrifos (Lorsban) and cayenne pepper extract (Hot Pepper Wax) as barrier treatments. All barrier treatments took place during the last week of March. We conducted visual inspections in mid-April and late April, the results of which are represented in Figures 2 and 3, repectively. Each of the treatments proved repellent to cutworms, inhibiting their climbing activity. Inspecting at intervals allowed us to better understand the efficacy of the barrier treatments over time.

FIGURE 2 |

|||

| Mid-April

Inspection of Cutworm Damage after Late-March Barrier Treatments

(2003) |

|||

|

|

FIGURE 3 |

|||

| Late-April

Inspection of Cutworm Damage after Late-March Barrier Treatments

(2003) |

|||

|

|

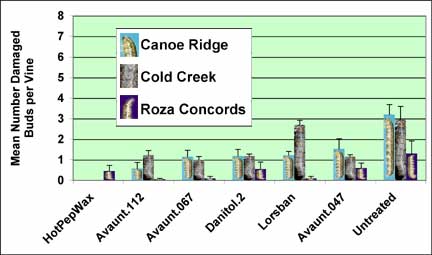

As part of our 2003 trials, we also tested a number of foliar treatments. These were applied about 10 days after the barrier treatments, in mid-April. Our foliar treatments at each trial site included the registered insecticides Lorsban and Danitol, the candidate insecticide indoxacarb (Avaunt), and Hot Pepper Wax. Avaunt was tested at three concentrations. ED NOTE: Indoxacarb is not registered for use on grapes in Washington. The results of our visual inspection conducted in late April are shown in Figure 4.

FIGURE 4 |

|||

| Late-April

Inspection of Cutworm Damage after Mid-April Foliar Treatments (2003) |

|||

|

|

Conclusions

Targeted insecticide barrier sprays are proving to be a promising method of treatment for reducing cutworm feeding injury in southeastern Washington grape vineyards. Not only are the treatments efficacious, they are cost-effective. Lorsban as a foliar spray runs about $40 per acre, while Danitol as a barrier treatment is about half that, $15 to $20 per acre. As we anticipate registration of zeta-cypermethrin in the near future, it has been estimated this product could further reduce the cost of cutworm control to $3 or less per acre when applied as a barrier treatment. Finally, because the barrier-treatment application method is targeted to the base of the plant, there is less disruption to the populations of non-target pests and beneficials, which is compatible with IPM principles.

We plan to have a recommendation on barrier treatment applications ready for grape growers by next spring. At this point, it appears that foliar treatments may soon be a thing of the past as a routine means of cutworm management in grapes. We believe barrier treatments will emerge as a clearly superior treatment, with foliar sprays applied only in dire emergencies as rescue insecticides.

Doug Walsh (dwalsh@tricity.wsu.edu), Holly Ferguson (hferguson@tricity.wsu.edu), and Ron Wight conduct entomology research and extension activities from WSU's Irrigated Agriculture Research and Extension Center (IAREC) in Prosser, (509) 786-2226.

Bye-Bye Birdie for Cutworms?Summer Research Project Targets Fruit Worms, Also Snags CutwormsAn attract-and-kill trap has been developed by Dr. Pete Landolt, a Research Entomologist at the USDA Wapato Entomology Research Facility. Landolt’s trap uses acetic acid and isoamyl alcohol as a feeding attractant lure. This lure is placed in the base of a modified badminton shuttlecock (aka "birdie"). Moth mortality occurs after the moth makes contact with the insecticide permethrin mixed in Teflon grease that is smeared onto the sides of the badminton birdie. ED. NOTE: This use is not registered on grapes in Washington. Landolt’s target pest in the tree fruit system has been the lacanobia fruit worm. However, he has observed substantial numbers of other moth species including the adult spotted cutworm attracted to and killed by these traps. An advantage this trap offers over traditional pheromone-based traps is that both males and females are attracted as opposed to pheromone-based traps that typically attract only males. We have received funding from the Wine Advisory Committee and the Washington State Commission on Pesticide Registration to test the possibility of reducing the spring 2004 cutworm population in vineyards by reducing the reproductive moth population in the summer and fall of 2003. - DW, HF, RW |

Go to this issue's Table of Contents

Go to Agrichemical and Environmental News Index

Go to WSPRS (Washington State Pest Management Resource Service) Home Page

Items in this section often appear in the words of the sponsoring organization or original news release. AENews editorial staff is not responsible for the accuracy of the content.

WSDA's Endangered Species Program Workshop to be Held August 4

Washington State Department of Agriculture will hold an Endangered Species Program workshop Monday, August 4th, 2003 in their Natural Resources Building (Room 175 A & B) from 9 am to noon. Agenda Items Include: an overview of the Endangered Species Act (ESA); ESA and Pesticides: Potential Implications for Use in Washington; WSDA's Endangered Species Program; and the State-Intiated Plan.

For further information, contact Bridget Moran, Endangered Species Program Coordinator, WSDA Pesticide Management Division, 1111 Washington Street SE, MS 42589, Olympia, WA 98504, (360) 902.1936, (360) 902.2093 (fax), or BMoran@agr.wa.gov.

Pesticide Stewardship Conference Slated for October

The 4th Annual National Pesticide Stewardship Alliance (NPSA) Conference is scheduled for October 19 through 22, 2003, in Tucson, Arizona. This year's theme is Stewardship Issues: Discussions for a Global Community. Focus topics will include the future of state pesticide disposal programs, residential pesticide stewardship, and label language pertaining to container disposal.

For more information on the conference and the NPSA organization, visit their Website:

http://www.npsalliance.org

XI International IUPAC Symposium on Mycotoxins and Phycotoxins

Call for Papers

The XI International IUPAC Symposium on Mycotoxins and Phycotoxins will be held in Bethesda, Maryland, from the 17th to the 21st of May, 2004.

The International Union of Pure and Applied Chemistry (IUPAC) Food Chemistry Commission initiated the series of International Symposia on Mycotoxins and Phycotoxins and the first was held in Kungalv, Sweden in 1973. Since then nine symposia have been held in Pulawy, Poland; Paris, France; Lausanne, Switzerland; Vienna, Austria; Pretoria, South Africa; Tokyo, Japan; Mexico City, Mexico; Rome, Italy and Guaruja, Brazil. The symposia have become the principal international interdisciplinary meeting on mycotoxins and phycotoxins. The most recent, held in Brazil (May 2000), focused on the global significance of mycotoxins and phycotoxins, their occurrence, assay proficiency, toxicology and risk assessment. The XI symposium will assess progress or advances made since Brazil 2000 in relation to overall goals of the series and the evolving global perspective of food safety. Internationally renowned guest scientists will highlight: advances in methodology; the value of risk assessment and its regulatory use; laboratory quality assurance and quality control, accreditation and method validation, particularly in developing countries. Advances in genomics for detection and evaluating the impact of mycotoxins and phycotoxins on human and animal health, as well as control strategies will be discussed. In addition, an estimated 200 posters will be presented. There will also be a “self assessment” of the IUPAC Symposia on Mycotoxins and Phycotoxins series from a historical and impact perspective. The symposium is of prime importance to educators and researchers worldwide.The Organizing and Scientific committees invite submission of abstracts for oral or poster presentation on cutting edge research in the topics listed below.

T1 – Novel sampling and analytical techniques

T2 – Advances in ecology and physiology

T3 – Chemistry and toxicology of mycotoxins and phycotoxins

T4 - Occurrence in food and feed of expected and new and emerging toxins

T5 – New technologies for assessing and predicting risk

T6 – Tailoring risk assessment/management to specific subpopulations

T7 – Solutions/preventative intervention: biocontrol, chemical modifications and salvage technologies,

T8 – Trade, regulations and quality assurance

T9 – Emerging issues in risk communication

T10- Mycotoxins in botanicals and traditional remedies

T11- GMOs, nanoscience and nanotechnologies.Abstracts are due by October 6, 2003, and must adhere to the following format.

1. 300 words or less, single-spaced, 12 font size and in English.

2. The title must be in CAPITAL letters.

3. Must contain author(s) name(s) and full address, including telephone and fax numbers and e-mail (where applicable)

4. Abstract must be precise and informative. Should contain a statement of the problem, objectives, methods, summary of results and conclusions, and application. It is not acceptable to say "results will be discussed" or “the paper will address…”

5. The title must be as brief as possible, but sufficient to indicate clearly the nature of the study and category.

6. Electronic (e-mail) submission is preferred (hnjapau@cfsan.fda.gov; strujill@cfsan.fda.gov; dpark@cfsan.fda.gov) but abstracts may also be faxed to 301 436 2644 (attn: IUPAC SYMPOSIUM) or PC floppies (MS word) mailed to the IUPAC XI Symposium on Mycotoxins and Phycotoxins Secretariat (Symposium Secretariat).

Regional Ag Health & Safety Conference

Mark your calendar now for the September 7-9, 2003 regional conference on agricultural health and safety issues. This timely conference will be held at the Holiday Inn Gateway in San Francisco. The theme for this year is "Challenges in Agricultural Health and Safety." This important meeting for agricultural professionals is jointly sponsored by the Western Center for Agricultural Health and Safety at UC Davis and the Pacific Northwest Agricultural Safety and Health Center at the University of Washington, Seattle, along with the Center for Occupational and Environmental Health at UC Berkeley.

The program themes include sessions on injuries and ergonomics, illnesses and diseases (including respiratory diseases and pesticide illnesses), and health and safety challenges faced by farmworkers.

A special feature of this year's conference will be breakfast discussion tables focusing on specific issues. Here is a chance to join in lively and informal discussions on topics of particular interest to you and meet others with similar interests.

More information can be found at http://agcenter.ucdavis.edu/Announce/AgChallenges2003.php.

Since its establishment in 1961, the Pesticide Advisory Board (PAB) has served Washington State by advising the Washington State Department of Agriculture (WSDA) director on issues related to new laws, enforcement, education, and budget. Among other roles, the board encourages open communication between the user community, interested parties, WSDA staff, and PAB members. The Washington State Legislature established the PAB in RCW 17.21.250. In 2001, a charter was adopted that clearly defined board activities. The Pesticide Advisory Board Charter states the board’s mission is to advise and provide the WSDA director with recommendations on issues related to the registration, distribution, use and disposal of pesticides in the state. In accomplishing this mission, PAB is asked to:1) Review, advise, and provide timely input to the agency director regarding any or all of the following issues:

- Any new or proposed changes to the Washington Administrative Code, Revised Code of Washington, legislation or policies.

- Any compliance, enforcement, education or registration issues.

- Any proposed significant change to department compliance, enforcement or registration policies or programs.

- Any proposed significant program and/or budget requests or changes.

2) Bring to the agency director any topics of concern or any proposals related to the use, distribution, and disposal of pesticides as well as pesticide education issues.

3) Conduct an efficient board process consisting of well-run meetings and comprehensive committee work.

The board meets on a quarterly basis or more often as needed. Meetings are open to the public and interested parties are encouraged to attend. For information on upcoming meeting schedules or meeting minutes, contact the WSDA at (360) 902-2012.

Click here for a list of current PAB members and their areas of specialty. Feel free to contact any member if you have general questions; concerns specific to a particular area should be directed to the most appropriate member or to the board chairman. If your issue is one with policy implications, it may either be brought to an existing ad-hoc committee, or to the full board for consideration and appropriate disposition.

Plastic Pesticide Container Recycling

The Washington Pest Consultants Association (WaPCA) has been involved in recycling plastic pesticide containers since the early 1990s in Washington State. Northwest Ag Plastics, Inc. is contracted to operate the recycling program.

For information on the program and the parameters for disposal, see the WSU Pesticide Education Program's Web page on the subject at

http://pep.wsu.edu/waste/wapca.html

For the 2003 collection schedules, see

http://www.nwagplastics.com/schedules/schedule.html

or see the individual PDF file for the area and time period in which you are interested:

Eastern WA • Western WA Early Season • Western WA Late Season

Go to this issue's Table of Contents

Go to Agrichemical and Environmental News Index

Go to WSPRS (Washington State Pest Management Resource Service) Home Page